Industry News

AUGUST 2024

Incxnnue x Lynxter product featured in Emily in Paris

European exhibitor Lynxter SAS, has teamed up with INCXNNUE to create the stunning 'COMETE' bag, showcased in Netflix's latest series of Emily in Paris!

This collaboration highlights the incredible potential of 3D-printed silicone in luxury fashion by showcasing how cutting-edge technology can redefine design possibilities. The use of 3D printing allows for intricate, customized patterns and textures that are not achievable through traditional methods.

Folding brain implants ‘could make epilepsy surgeries safer’

Wacker expands in medtech silicones with Bio Med Sciences deal

European Exhibitor WACKER have expanded their footprint in the medtech silicone sector! The German-based company has recently taken over Bio Med Sciences, Inc. This strategic move enhances Wacker's capabilities in developing silicone-coated healthcare products, particularly for medical devices and advanced wound care applications!

‘Made in China’ products in great demand as Paris Olympics draws near

JULY 2024

Preventing power pole-top fires with a silicone composite

Engineers at RMIT University have collaborated with the UNSW to create a silicone composite helping to prevent power pole top fires! The universities have developed a fire and electrical spark-resistant power-pole insulator using a silicone composite. This new material addresses the significant issue of pole-top fires and is composed of silicone rubber, aluminium hydroxide, volcanic ash-derived nanoclay, and chopped fibreglass. This combination enhances hydrophobic properties, flame retardancy, and structural integrity.

Self-healing 'living skin' can make robots more humanlike — and it looks just as creepy as you'd expect

Researchers have developed a novel approach to robotic skin using cultured cells and silicone, creating lifelike, self-repairing skin that adheres seamlessly to robots! This innovation could revolutionize human-robot interaction, ensuring durability and a more human appearance. Learn more about the potential to transform robotics in the latest study published in Cell Reports Physical Science.

Guill introduces 500 Series rubber/silicone extrusion crosshead

Guill Tool & Engineering's latest innovation: The 500 Series Rubber/Silicone Extrusion Crosshead. Designed for elastomeric compounds, it features the revolutionary MAGS adjustment system for precise, effortless adjustments. The patented cam lock design speeds up cleaning and changeovers, and the new flow inlet channel ensures balanced material flow by reducing shear and heat.

Stretchable electrode recreates sensations on skin

Researchers from San Diego have developed a soft, stretchable electrode attached to a silicone patch that can be worn like a sticker on the fingertip or forearm. The electrode is connected to an external power source via wires. By sending a mild electrical current through the skin, the device can produce sensations of pressure or vibration depending on the signal’s frequency."

JUNE 2024

Discover the Top 9 Silicone Industry Trends in 2024

StartUs Insights shares their latest report on the Silicone Industry's Top Trends of 2024!

The report analysed over 500 companies and acknowledged their advancements in the industry, focusing on "modern silicone technologies like silicone 3D printing, advanced adhesives, functional coatings, and more. Further, novel silicone formulations enhance resistance to extreme temperatures and pressures, expanding their potential in demanding high-performance materials."

Wacker expands in medtech silicones with Bio Med Sciences deal

European Exhibitor WACKER have expanded their footprint in the medtech silicone sector.

The German-based company has recently taken over Bio Med Sciences, Inc. This strategic move enhances Wacker's capabilities in developing silicone-coated healthcare products, particularly for medical devices and advanced wound care applications!

May 2024

Dow India signs carbon neutral façade agreement with Glass Wall Systems

Conference Sponsor Dow and GLASS WALL SYSTEMS have collaborated to supply DOWSIL Façade Sealants!

"Silicone sealants used in façades are already known for their positive contribution to lowering the operating carbon emissions coming from the cooling and heating of buildings, as they provide durable bonding in insulated prefabricated façade elements," said Jean-Paul HAUTEKEER, Global Marketing Director for Building & Infrastructure at Dow Consumer Solutions.

“APPLICATIONS FOR HIGH-PERFORMANCE, OPTICALLY CLEAR SILICONE RUBBER” WEBINAR BY RDABBOTT

Join this free webinar on Wednesday, May 29, 2024, from 10:00 – 11:00 AM (ET).

Delve into innovative applications alongside three Dow experts who will be shedding light on its uses in general and automotive LED lighting!

2024 SEAL Sustainable Product Award recognizes Elkem

We are commemorating Silicone Expo USA exhibitor, Elkem on their win at the 2024 SEAL Awards!

Elkem won an award for their product BLUESIL™ TCS 7538 LE, hailed as a "low-VOC, high-compatibility silicone innovation for automotive airbag coating."

April 2024

Univar and Dow expand partnership for construction silicone products in CEE

Our Conference Sponsors, Dow Performance Silicones, have expanded their partnership with Univar Solutions to distribute construction silicone products across Central and Eastern Europe (CEE).

This collaboration aims to provide customers in the region with a broader selection of construction solutions known for their durability and protective qualities in challenging environmental conditions. The products are designed to extend the lifespan of substrates and building materials, reduce maintenance costs and time, and enhance aesthetic appeal.

Where Silicon Materials Can Replace PFAS

Robert Ruckle, Global Marketing and Sales Director at Siltech Corporation deep dives into the alternatives to PFAS compounds in response to recent #EPA and #ECHA interest and impending restrictions.

Discover how Siltech offers specialized silicone expertise as a potential replacement, addressing critical performance criteria such as surface tension, coefficient of friction, water repellency, oleophobicity, and chemical stability.

Tenchy Silicone Revolutionizes Industries with Innovative Polyester Braided Reinforced Silicone Hoses

This week Shenzhen Tenchy Silicone and Rubber Co.,Ltd unveils a game-changing innovation tailored for diverse industries, from medical to aerospace. These hoses redefine performance with unmatched flexibility, durability, and resistance to high temperatures, chemicals, UV rays, and ozone. This innovative product stands as the cornerstone of industrial innovation, guiding businesses towards success in ever-changing environments!

Family reunion in Amsterdam

At the end of February 2024, the industry, one could almost say the family, of the European silicone rubber industry met in Amsterdam. Antje Hanisch, Operations Manager at Silcomp Group in Lutherstadt Wittenberg, describes it as a 'family reunion in Amsterdam' for the European silicone rubber industry.

March 2024

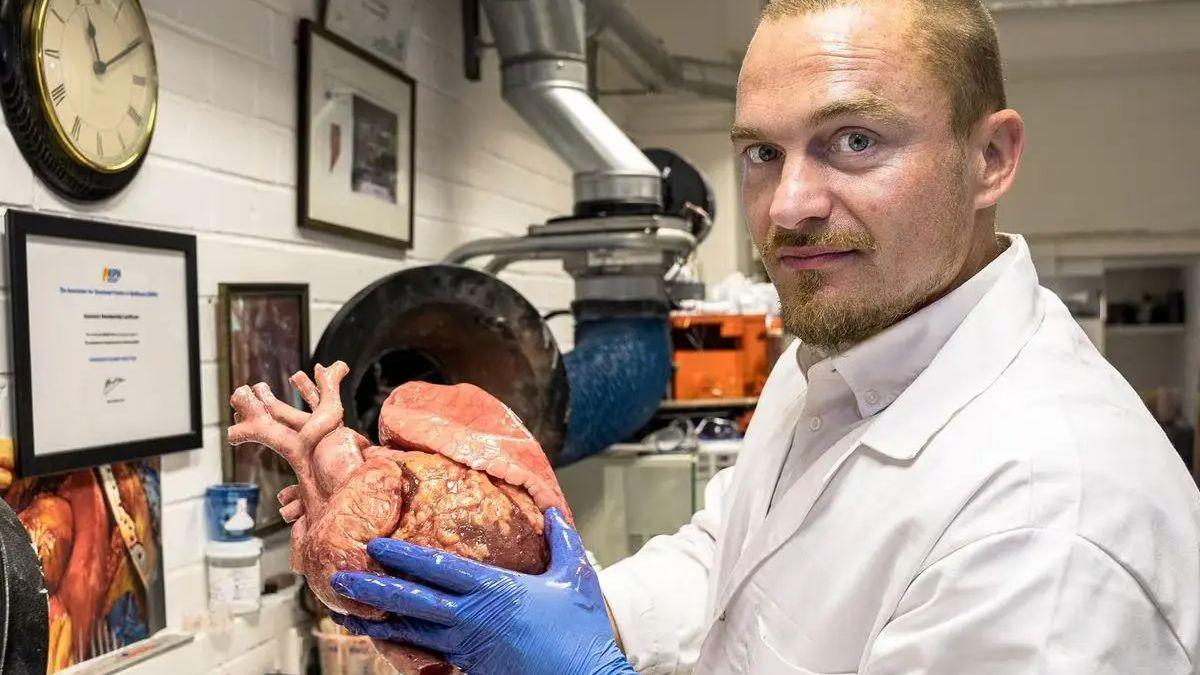

Bleeding and beating heart models created to help train transplant surgeons

Nottingham Trent University have created hyper-realistic bleeding and beating heart models crafted with 3D Silicone Printing Technology, offering surgeons unparalleled hands-on experience - innovating medical education for safer surgeries worldwide.

“The aim is to give surgeons the opportunity to learn the technical aspects of organ transplant surgery and experience the tactile aspects of removing a failing heart and connecting a different healthy one, identifying and suturing the vessels that keep the donor heart in place."

Elkem develops new iron-silicon powder for 3D printing of electrical motors

In partnership with VTT, Siemens, and Stellantis, Elkem has introduced a revolutionary iron-silicon powder for 3D printing electrical motors, marking a significant breakthrough in manufacturing!

“This is a project with the potential to transform motor parts manufacturing. We have successfully created a new specialized powder with good printability based on silicon steel (with additives). 3D printed components show enhanced flexibility and competitive magnetic properties”